The «heart» of pumped hydroelectric energy storage is located deep inside a mountain: In a cavern, pumps and turbines are installed in huge halls. The access tunnels are usually several hundred meters long. Individual company fire services have recognized the similarities between their facilities and other underground transport systems such as tunnels. They use the training infrastructure of the International Fire Academy in Lungern and their teachings for their preparation.

Great penetration depths as a central commonality

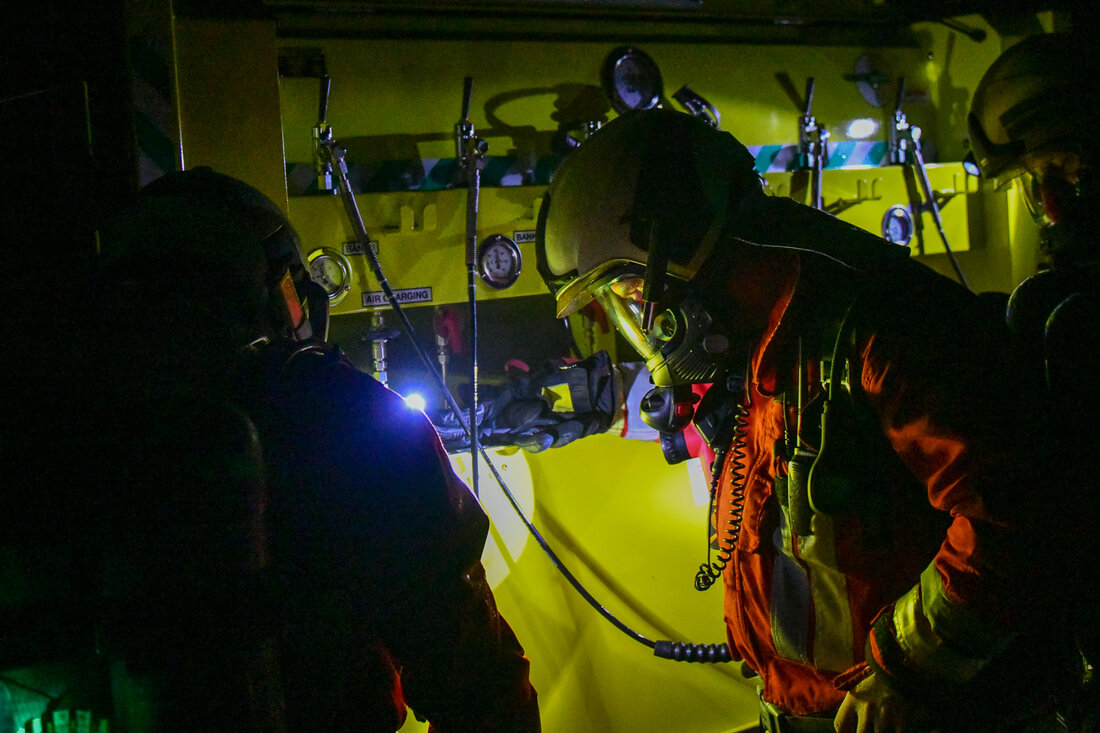

In the event of a fire, long distances to the site are incredibly strenuous and particularly dangerous for firefighters. Because the aim is to penetrate smoke-filled areas, the International Fire Academy has defined the term «penetration depth». It refers to the distance from the safe area of a building to the working area of the fire service. The penetration depth is rated as «great» if this route is more than 80 m long.

In pumped hydroelectric energy storages, such penetration depths can arise, for example, with a lorry fire in an access tunnel or with a fire in a cavern of more than 80 m in length, as long as there are no lateral accesses. The Tunnel Firefighting Procedure of the International Fire Academy shows how such great penetration depths can be mastered.

Training during continuous power plant operation

Pumped hydroelectric energy storage play an essential role for a stable power supply. For example, they compensate for fluctuations in electricity production of renewable energies from wind and solar radiation. In order to ensure a secure power supply, the power plants are on the grid without interruption.

For firefighters, this means limited training opportunities, as the operation of the plant must not be disturbed or interrupted. Basically, all necessary practical tasks can be trained in the power plant, as well as communication and orientation. A smoke test was also possible in a power station belonging to the Schluchseewerk AG, with the International Fire Academy providing counsel.

However, a firefighting attack and the heat load in the event of a fire cannot be displayed in a pumped hydroelectric energy storage. Special training tunnel systems are suitable for this purpose, which offer realistic operating conditions.